SAC

Recycling

Recycling of Platinum Group Metals

Our development in the sector

Group companies in the sector:

Process

Delivery

Sorting

Grinding

Analysis

Packing

Transport

Factors

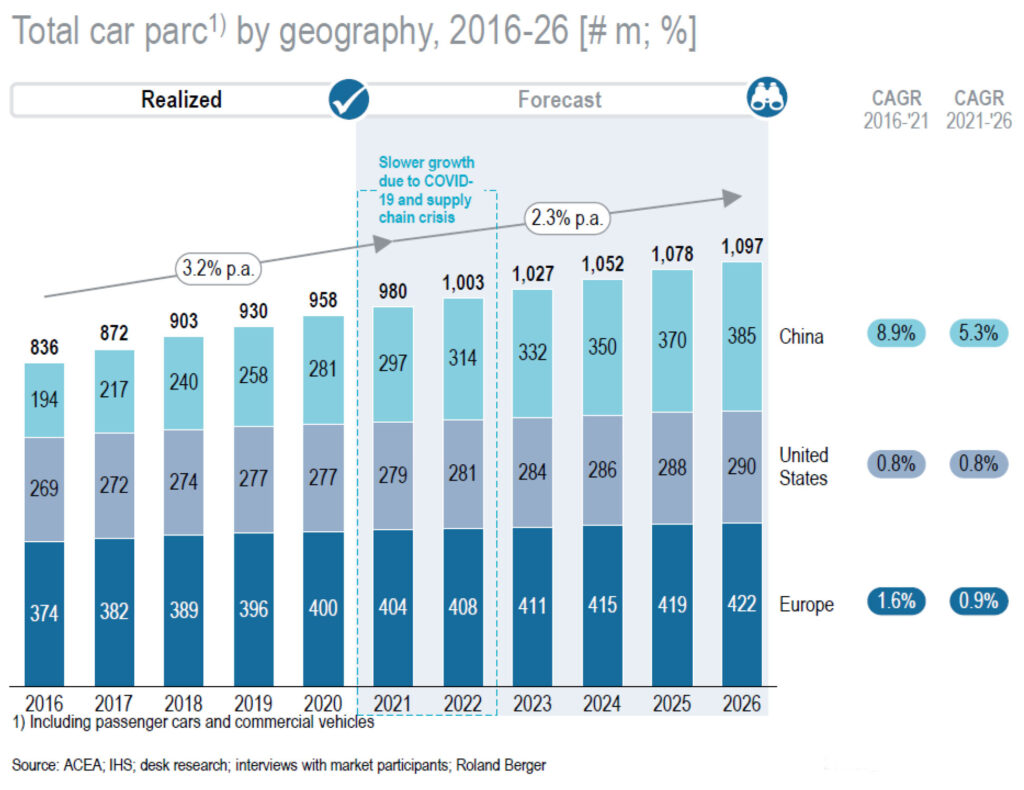

Strong volume growth is driven by historic and future car production, increased vehicle retirements and increased PGM (platinum group metals) loading.

Forecasts

The market for recycling used automotive catalytic converters is expected to grow into the 2040s.

Market position

In 2022, Elemental Group companies processed more than 6,000 tons of used automotive catalysts containing valuable metals. This represents a 9 percent increase from 2019, driven primarily by expansion in the United States – both through organic growth and continued M&A activity.

Platinum Group Metals

Each year, more than 400 tons of platinum group metals (PGM) are mined worldwide, including platinum, palladium, rhodium, iridium and ruthenium. Recycling spent automotive catalytic converters is key to increasing the recovery of these valuable metals worldwide.

Global PGM resources

Global resources of platinum group metals are estimated at 66 thousand tonnes, 95% of which are located in South Africa.

Recycling of automotive catalytic converters

A significant part of PGM comes from recycling used automotive catalytic converters and consist of 68% platinum, 84% palladium and 100% rhodium.

Recycling of electrical equipment

Platinum group metals are also recovered from electrical equipment, with 2% of the platinum and 16% of the palladium coming from this source.

Mining costs vs. recycling

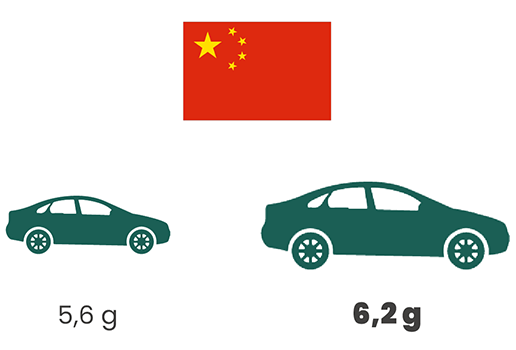

PGM mining is much more expensive than recycling. The platinum content in one ton of ore is only 2-6 g, while one ton of catalysts contains about 2 kg of platinum group metals.

Car catalytic converters

A car catalytic converter is a component of the exhaust system that reduces the amount of harmful substances contained in exhaust fumes. There are two types of catalytic converters

-

Ceramic catalysts

Automotive catalytic converters consist of a stainless steel housing and a ceramic insert whose surface is coated with platinum group metals.

-

Metal catalysts

Constructed from a block of metal made of layers of corrugated foil, forming a network of channels which, similarly to the ceramic catalytic converter insert, contains platinum group metals.

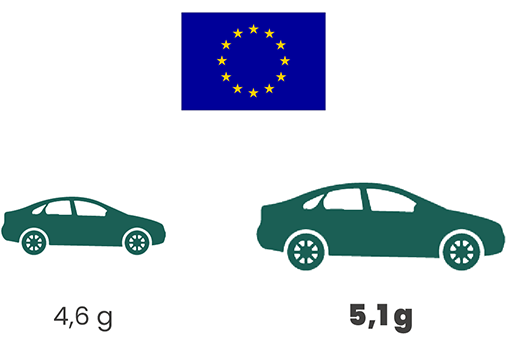

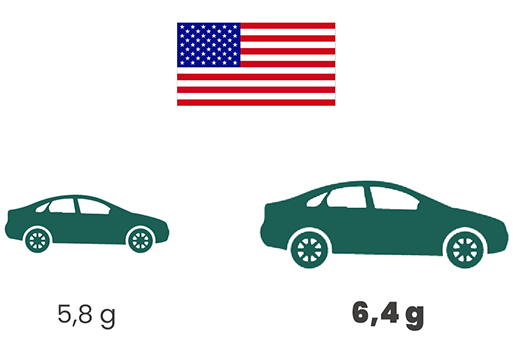

Platinum group metals, mainly platinum, palladium and rhodium, stimulate the reactions of carbon monoxide, hydrocarbons and nitrogen oxides contained in exhaust gases, which results in a reduction of harmful emissions. The content of PGM in automotive catalytic converter inserts is on average from 0.2% to 0.3%, and this level depends on the age of the car and the type of fuel burned.

Automotive catalyst recycling processes aim to recover valuable metals for reuse. Automotive catalyst recycling can recover up to 95% of the platinum content, and also saves significant amounts of energy compared to traditional mining (processing 1 ton of used catalysts prevents the extraction of 150 tons of ore or 400 tons of waste rock).

Vehicle production currently generates about two-thirds of the total demand for platinum group metals. A factor that will affect the growth in demand for PGMs in the coming years is the increasing stringent emission standards. Car manufacturers will be forced to introduce increasingly advanced design solutions to meet the requirements, which may result in an increase in demand for PGMs.

Platinum will also play an important role in the production of green hydrogen. Hydrogen produced by electrolysis of water is called “green” hydrogen, and platinum is used as a catalyst in the electrolysis process.